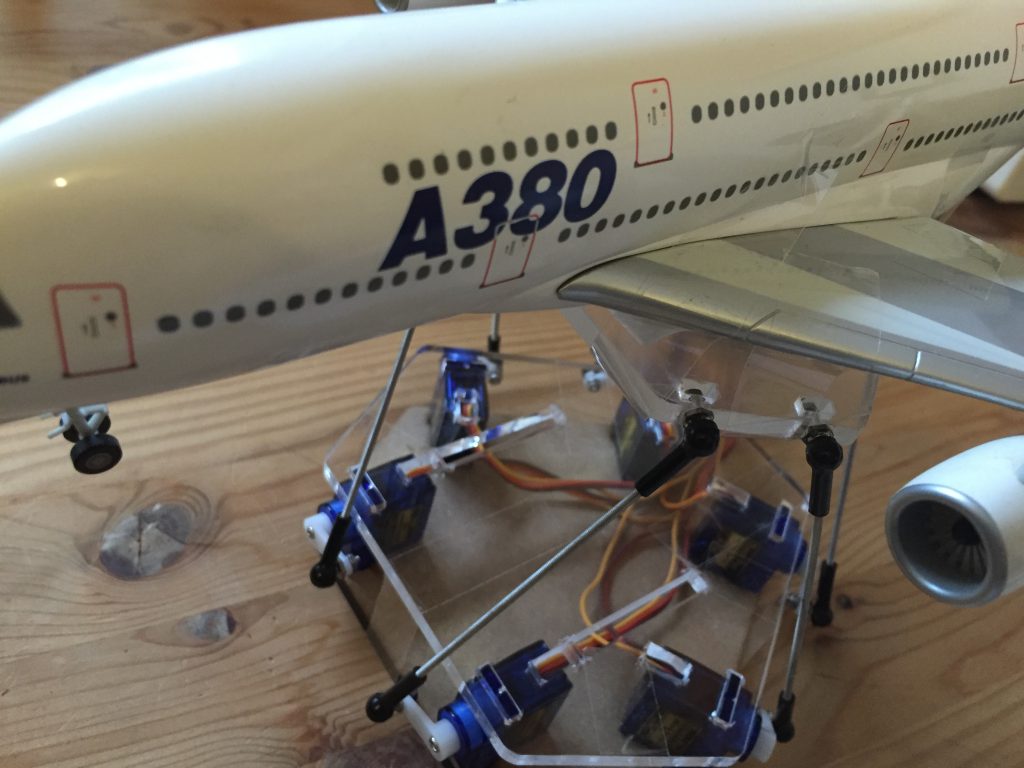

Hier mal ein erster Test einer 6DOF Stewart Plattform auf Servo und arduino-basis in Verbindung mit SIMTOOLS.

/*

//********************************************************************************************

// RC Model Servo

// Original code By EAOROBBIE (Robert Lindsay)

// Completely mangled by aarondc

// For free use for Sim Tool Motion Software

// Changed by SIM-PC.de for 6DOF

//********************************************************************************************

#include

//#define DEBUG 1 // comment out this line to remove debuggin Serial.print lines

const int kActuatorCount = 6; // how many Actuators we are handling

// the letters ("names") sent from Sim Tools to identify each actuator

// NB: the order of the letters here determines the order of the remaining constants kPins and kActuatorScale

const char kActuatorName[kActuatorCount] = { 'A', 'B', 'C', 'D', 'E', 'F' };

const int kPins[kActuatorCount] = {2, 3, 4, 5, 6, 7};

const int kActuatorScale[kActuatorCount][6] = { { 0, 179 } , // 1 Actuator scaling

{ 0, 179 } , // 2 Actuator scaling

{ 0, 179 } , // 3 Actuator scaling

{ 0, 179 } , // 4 Actuator scaling

{ 0, 179 } , // 5 Actuator scaling

{ 0, 179 } // 6 Actuator scaling

};

const char kEOL = '~'; // End of Line - the delimiter for our acutator values

const int kMaxCharCount = 3; // some insurance...

Servo actuatorSet[kActuatorCount]; // our array of Actuators

int actuatorPosition[kActuatorCount] = {90,90,90,98,90,90}; // current Actuator positions, initialised to 90

int currentActuator; // keep track of the current Actuator being read in from serial port

int valueCharCount = 0; // how many value characters have we read (must be less than kMaxCharCount!!

// set up some states for our state machine

// psReadActuator = next character from serial port tells us the Actuator

// psReadValue = next 3 characters from serial port tells us the value

enum TPortState { psReadActuator, psReadValue };

TPortState currentState = psReadActuator;

void setup()

{

// attach the Actuators to the pins

for (int i = 0; i < kActuatorCount; i++)

actuatorSet[i].attach(kPins[i]);

// initialise actuator position

for (int i = 0; i < kActuatorCount; i++) updateActuator(i); Serial.begin(38400); // opens serial port at a baud rate of 9600 } void loop() { } // this code only runs when we have serial data available. ie (Serial.available() > 0).

void serialEvent() {

char tmpChar;

int tmpValue;

while (Serial.available()) {

// if we're waiting for a Actuator name, grab it here

if (currentState == psReadActuator) {

tmpChar = Serial.read();

// look for our actuator in the array of actuator names we set up

#ifdef DEBUG

Serial.print("read in ");

Serial.println(tmpChar);

#endif

for (int i = 0; i < kActuatorCount; i++) {

if (tmpChar == kActuatorName[i]) {

#ifdef DEBUG

Serial.print("which is actuator ");

Serial.println(i);

#endif

currentActuator = i; // remember which actuator we found

currentState = psReadValue; // start looking for the Actuator position

actuatorPosition[currentActuator] = 0; // initialise the new position

valueCharCount = 0; // initialise number of value chars read in

break;

}

}

}

// if we're ready to read in the current Actuator's position data

if (currentState == psReadValue) {

while ((valueCharCount < kMaxCharCount) && Serial.available()) {

tmpValue = Serial.read();

if (tmpValue != kEOL) {

tmpValue = tmpValue - 48;

if ((tmpValue < 0) || (tmpValue > 9)) tmpValue = 0;

actuatorPosition[currentActuator] = actuatorPosition[currentActuator] * 10 + tmpValue;

valueCharCount++;

}

else break;

}

// if we've read the value delimiter, update the Actuator and start looking for the next Actuator name

if (tmpValue == kEOL || valueCharCount == kMaxCharCount) {

#ifdef DEBUG

Serial.print("read in ");

Serial.println(actuatorPosition[currentActuator]);

#endif

// scale the new position so the value is between 0 and 179

actuatorPosition[currentActuator] = map(actuatorPosition[currentActuator], 0, 255, kActuatorScale[currentActuator][0], kActuatorScale[currentActuator][1]);

#ifdef DEBUG

Serial.print("scaled to ");

Serial.println(actuatorPosition[currentActuator]);

#endif

updateActuator(currentActuator);

currentState = psReadActuator;

}

}

}

}

// write the current Actuator position to the passed in Actuator

void updateActuator(int thisActuator) {

actuatorSet[thisActuator].write(actuatorPosition[thisActuator]);

}

Da doch einige Anfragen zur Ansteuerung eines TM1638 mit dem rcc gekommen sind, habe ich hier mal ein einfaches Beispiel für eine Drehzahlanzeige gemacht.

//https://github.com/rjbatista/tm1638-library

#include

// define a module on data (DIO) pin 8, clock (CLK) pin 9

// and strobe (STB0)pin 10

TM1638 module(8, 9, 10);

String ver = "2.0.0.0";

const int nChar = 30; // size of char

String inString = ""; // a string to hold incoming data

boolean stringComplete = false; // whether the string is complete

int vRpm;

void setup()

{

Serial.begin(38400);

}

void readdata() {

if (stringComplete) {

if (inString.substring(0, 2) == "RR") {

vRpm = inString.substring(2, 6).toInt();

module.setDisplayToDecNumber(vRpm * 10,0,false);

}

inString = "";

stringComplete = false;

}

}

void serialReadEvent() {

while (Serial.available()) {

char inChar = (char)Serial.read();

inString += inChar;

if (inChar == ';') {

stringComplete = true;

}

}

}

void loop() {

serialReadEvent();

readdata();

}

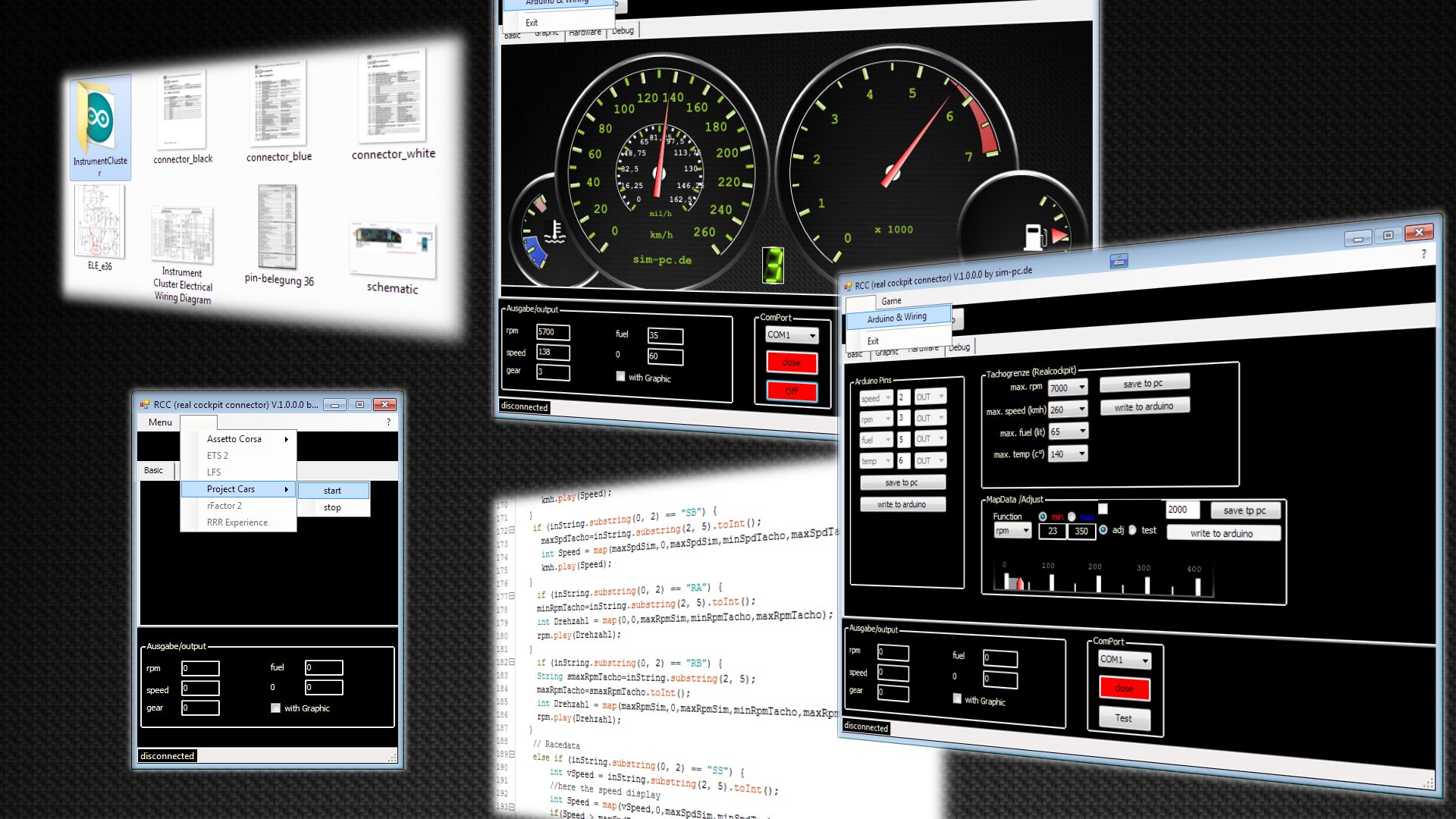

Im moment arbeite ich an eine stark erweiterte Version vom

rcc (real cockpit connector) als kompletter Gamedash zur Ansteuerung von unterschiedlichster Hardware.

Ein einfaches Möglichkeit um z.b. eine Drehzahlanzeige in einem Cockpit zu steuern wäre die Kontrolle mit einem Servo.

/*

This is a servo sample for rcc with rpm

http://www.arduino.cc/en/Tutorial/Sweep

*/

#include Servo myservo; // create servo object to control a servo,

//twelve servo objects can be created on most boards

String ver = "2.0.0.3";

const int servPin = 9; // Servo Pin

const int nChar = 30; // size of char

String inString = ""; // a string to hold incoming data

boolean stringComplete = false; // whether the string is complete

void setup() {

myservo.attach(servPin); // attaches the servo to the servo object

inString.reserve(nChar);

Serial.begin(38400);

}

void readdata() {

if (stringComplete) {

if (inString.substring(0, 2) == "RR") {

int vRpm = inString.substring(2, 6).toInt();

int pos = map(vRpm, 0, 800, 255, 0);

myservo.write(pos);

}

inString = "";

stringComplete = false;

}

}

void serialReadEvent() {

while (Serial.available()) {

char inChar = (char)Serial.read();

inString += inChar;

if (inChar == ';') {

stringComplete = true;

}

}

}

void loop() {

serialReadEvent();

readdata();

}

Da ich nicht unbedingt der Handbuchschreiber bin, habe ich mal ein einfaches kurzes Tutorial zum „rcc“ als Video hochgeladen.

Das Programm kann wahrscheinlich ab dem 23.01.2016 hier geladen werden.

Falls probleme mit dem Video sind, hier der Youtubelink: https://youtu.be/WWnBEGLMBAk

Mit 3 Kabel, Anzahl x Led’s, am Arduino ansteuern.

das Shift Register Breakout – 74HC595 mit Hardware SPI

Demo (8 x Led & 1 x 7 segment) mit 2 x 74HC595

#include <SPI.h>

// Mega2560 74HC595 ARDUINO SPI

int dataPin = 11; // 51 SER = MOSI

int latchPin = 10; // 53 RCLK = SS

int clockPin = 13; // 52 SRCLK = SCLK

int N1[9] = {63,6,91,79,102,109,124,7,127};

int N2[9] = {0,1,3,7,15,31,63,127,255};

void setup()

{

pinMode(latchPin, OUTPUT);

digitalWrite(latchPin, LOW);

//Setup SPI

SPI.setBitOrder(MSBFIRST);

SPI.begin();

}

void loop() {

for (byte i=0; i < 9; i++)

{

writeOutput(N1[i], N2[i]);

delay(500);

}

}

void writeOutput(int b1, int b2)

{

digitalWrite(latchPin, HIGH); // Pull latch LOW to send data

SPI.transfer(b1);

SPI.transfer(b2);

digitalWrite(latchPin, LOW); // Lower the latch to apply the changes

}

Alle funktionen des Tacho, Ganganzeige, eine 8 stellige konfigurierbare LED-Anzeige für Rpm

#include

#include

char kind_of_data;

// shiftpoint #############

int ShiftPoint = 0;

int RpmSimTools = 6500; // Schaltpunkt vorbelegen

int LimitRange = 0;

int UnderShiftPoint;

int OverShiftPoint;

int OverShift;

int UnderShift;

int ButtonState;

int LastButtonState = LOW;

long lastDebounceTime = 0;

long debounceDelay = 5;

//LED rpm

int rpmLED = 0;

// 7segment Common Cathode

int Gear;

int GearLight = 0;

int N1[9] = {63,6,91,79,102,109,124,7,80}; // 0 1 2 3 4 5 6 7 r

//arduino pins

int prpm = 2;

int pkmh = 3;

int ful = 5; // pwm

int tmp = 6; // pwm

int capture_button = 4; //shift point capture button

int analog_adj_pot = 0; // adjusting poti

//arduino spi pins nach 74HC595 (Shiftregister)

int latchpin = 10; // blaues kabel >> RCLK (Register clock)

int clockpin = 13; // grünes kabel >> SRCLK (Shift register clock)

int datapin = 11; // gelbes kabel >> SER (Serial data input)

// Tone

Tone kmh;

Tone rpm;

void setup(){

pinMode(latchpin, OUTPUT);

pinMode(ful, OUTPUT);

pinMode(tmp, OUTPUT);

pinMode(capture_button,INPUT);

digitalWrite(latchpin, LOW);

//Setup SPI

SPI.setBitOrder(MSBFIRST);

SPI.begin();

//Setup TONE

kmh.begin(pkmh);

rpm.begin(prpm);

Serial.begin(115200);

// Vorbelegung auf 50°c

analogWrite(tmp,85);

// Vorbelegung auf 30 Ltr.

analogWrite(ful,95);

}

void CheckButtonPress() { // shiftlight

int reading = digitalRead(capture_button);

if (reading != LastButtonState){

lastDebounceTime = millis();

}

if ((millis() - lastDebounceTime) > debounceDelay) {

if (reading != ButtonState){

ButtonState = reading;

if (ButtonState == HIGH){

ShiftPoint = RpmSimTools;

}

}

}

LastButtonState = reading;

}

void CheckShiftLightAdj() { // shiftlight nachjustieren

LimitRange = analogRead(analog_adj_pot);

int RpmAdjust = map(LimitRange, 1, 1023, 0, 2000);

UnderShift = RpmAdjust;

OverShift = RpmAdjust;

}

void SetLimits() { // shiftlight

UnderShiftPoint = ShiftPoint - UnderShift;

OverShiftPoint = ShiftPoint + OverShift;

}

void ReadData(){

if(Serial.available() > 0) {

kind_of_data = Serial.read();

delay(1);

int Data100 = Serial.read() - '0';

delay(1);

int Data10 = Serial.read()- '0';

delay(1);

int Data1 = Serial.read()- '0';

//Daten anpassen: aus 1 wird 001, aus 10 wird 010 etc.

while (Data1 < 0) {

Data1 = Data10;

Data10 = Data100;

Data100 = 0;

}

int Data = 100*Data100 + 10*Data10 + Data1;

// Speed

if (kind_of_data == 'S') {

int Speed = map(Data,0,255,0,318);

// Gauge begrenzen

if(Speed > 318) {

Speed = 318;

kmh.play(Speed);

}

else if((Speed <= 318) && (Speed >= 25)) {

kmh.play(Speed);

}

else if(Speed < 25) {

kmh.stop();

}

}

// Drehzahl

else if (kind_of_data == 'R') {

RpmSimTools = Data*10;

int Drehzahl = map(Data,0,700,0,350);

if(Drehzahl > 350) {

Drehzahl = 350;

}

if(Drehzahl < 025) {

Drehzahl = 000;

}

rpm.play(Drehzahl);

}

// Gang

else if (kind_of_data == 'G') {

Gear = Data;

if (Gear == 9) { // rückwärts

GearLight = N1[8];

}

if (Gear == 0) { // neutral

GearLight = N1[0];

}

if (Gear == 1) { // 1 gang

GearLight = N1[1];

}

if (Gear == 2) { // 2 gang

GearLight = N1[2];

}

if (Gear == 3) { // 3 gang

GearLight = N1[3];

}

if (Gear == 4) { // 4 gang

GearLight = N1[4];

}

if (Gear == 5) { // 5 gang

GearLight = N1[5];

}

if (Gear == 6) { // 6 gang

GearLight = N1[6];

}

if (Gear == 7) { // 7 gang

GearLight = N1[7];

}

}

//Tankinhalt

else if (kind_of_data == 'F') {

int Tankinhalt = map(Data,0,65,13,155);

if(Tankinhalt > 155) {

Tankinhalt = 155;

}

if(Tankinhalt < 13) {

Tankinhalt = 13;

}

analogWrite(ful,Tankinhalt);

}

//Temperatur

else if (kind_of_data == 'T') {

int Temperatur = map(Data,0,140,140,0);

analogWrite(tmp,Temperatur);

}

DisplayLeds();

}

}

void DisplayLeds(){

if (RpmSimTools < UnderShiftPoint *0.25){

rpmLED=0;

}

if (RpmSimTools >= UnderShiftPoint *0.25){

rpmLED=1;

}

if (RpmSimTools >= UnderShiftPoint *0.5){

rpmLED=3;

}

if (RpmSimTools >= UnderShiftPoint *0.75){

rpmLED=7;

}

if (RpmSimTools >= UnderShiftPoint){

rpmLED=15;

}

if (RpmSimTools >= ShiftPoint -500){

rpmLED=31;

}

if (RpmSimTools >= ShiftPoint){

rpmLED=63;

}

if (RpmSimTools >= OverShiftPoint -500){

rpmLED=127;

}

if (RpmSimTools >= OverShiftPoint){

rpmLED=255;

}

digitalWrite(latchpin, HIGH);

SPI.transfer(GearLight); // Ganganzeige

SPI.transfer(rpmLED); // LED's Drehzahl

digitalWrite(latchpin, LOW);

}

void loop(){

CheckButtonPress();

CheckShiftLightAdj();

SetLimits();

ReadData();

}

Die passende GameDash konfiguration findet ihr >> hier <<